Product Details

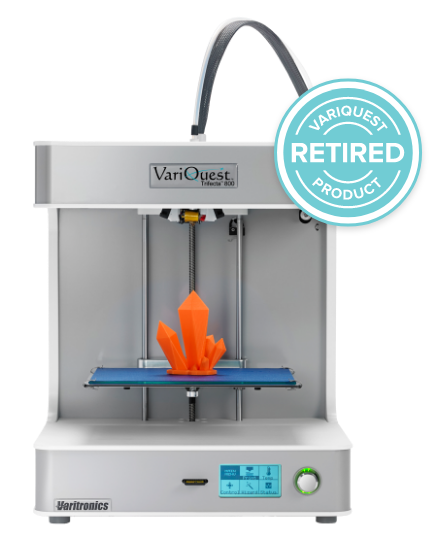

Trifecta® 800

STEM-based learning and 3D printing into school curriculum with content aligned to national and state standards.We’re sorry, this product is no longer available.

Product Details

Technical Info

Trifecta® 800

FAQS

Trifecta® 800

After slicing a file on my PC or Design Center, how do I print to my Trifecta?

What types of files are accepted for Trifecta 800? Is there a certain file type thats better?

Where can I design a file?

Where can I find a file to print instead of designing it myself?

Why do I need to cover the bed with blue painters tape? Can I use any type of tape?

Do I need to use a specific SD card?

Is Trifecta integrated with the Design Center Software?

Can I design a 3D object in the Trifecta Software?

What accessories do I need to get started?

What are 3D prints made of?

What file types slice fastest? What size should they be under?

What if my Design Center or PC doesnt have an SD card reader?

What is slicing?

What is the minimum and recommended computer requirements for the Trifecta Software?

How does 3D printing work?

How long is the shelf life of the filament if it is NOT stored in an optimal environment?

How long is the shelf life of the filament once it has been opened?

How long is the shelf life on an unopened box of filament?

Can I use other filament types or brands?