Product Details

Cutout Maker 1800 Digital Die-Cut Machine

Designed specifically for schools to help teachers and students automatically cut letters, numbers, manipulatives, shapes, and more with ease.Downloadable Content

View All Content

Butterfly Shape Pack

Welcome the Spring season with 6 new butterfly shapes for the Cutout Maker 1800!

Included in this install:

- Butterfly Solid Shape 01

- Search ID: ANI2034

- Butterfly Solid Shape 02

- Search ID: ANI2035

- Butterfly Solid Shape 03

- Search ID: ANI2036

- Layered Butterfly – Front Shape

- Search ID: ANI2037

- Layered Butterfly – Solid Shape

- Search ID: ANI2038

- Monarch Butterfly – Solid Shape

- Search ID: ANI2039

Looking for more content to print on your Cutout Maker 1800 Digital Die-Cut System? Check out our Cutout Maker Content Guide organized by title, lesson, and type!

Shape Pack 2

Get ready for summer with these brand new shapes for your Cutout Maker:

– Pellet Smoker (SEA260)

– Sand Pail (SEA261)

– Bubble Wand (SEA262)

– Bubble Wand Bubble (SEA263)

– Bubble Formula (SEA264)

– Motion Lamp (HOM305)

Looking for more content to print on your Cutout Maker 1800 Digital Die-Cut System? Check out our Cutout Maker Content Guide organized by title, lesson, and type!

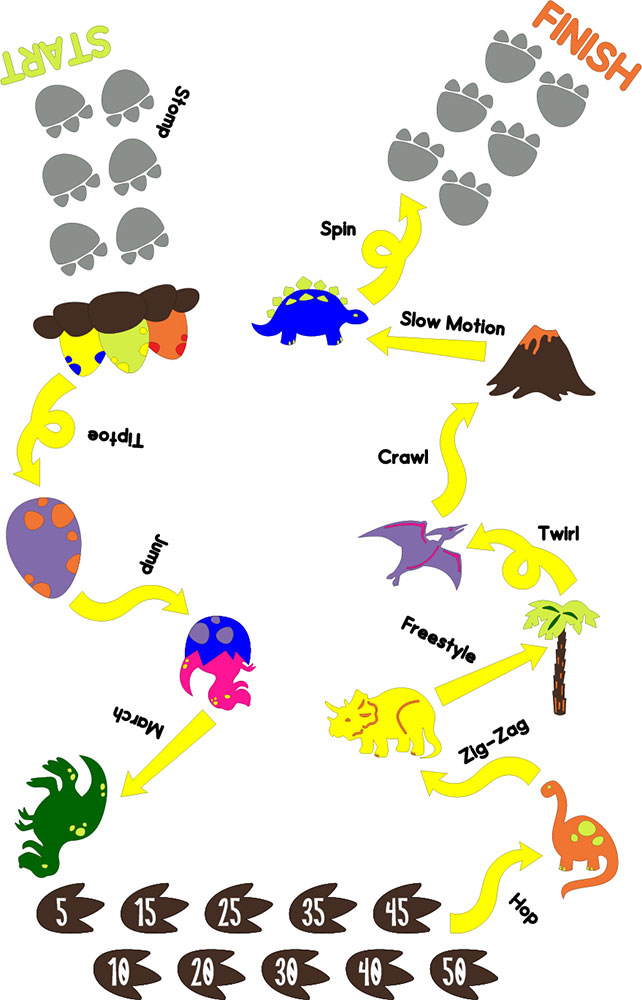

Dinosaur Sensory Path

Take a trip back to prehistoric times with our newest sensory path! Download our full lesson plan activity for this path, created in partnership with Cathy Henry of Free Word Work and The Curriculum Corner, complete with card templates, games, and more!

*Must have Premium Access in order to install

Looking for more content to print on your Cutout Maker 1800 Digital Die-Cut System? Check out our content guide organized by title, lesson, and type!

Cutout Maker Content Guide: https://resources.variquest.com/tools/cutout-maker-content-guide/

Product Details

Request Custom Shape

Simply follow these 4 steps to get started!

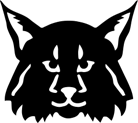

Want to be able to cut your school’s mascot on your Cutout Maker? How about a logo your student designed in class? With our custom Shape Program you can personalize your walls and bulletin boards with shapes that are tailored to your school.

1. Choose how you want your shape designed

To best suit your needs, several options are available for Custom Shape design in addition to our Standard Custom Shape. When you purchase a Custom Shape you will recieve a Standard Custom Shape designed from the image submitted. If you are looking for Custom Shape to fill a specific need, such as a vinyl decal, any of the Additional Design Styles listed below may be added to your order for an additonal fee per design style selected. Based on the descriptions below, determine which type of cut shape is right for you. Modifications will need to be made to the original design for any of the following options in order to create a successful cut shape, however keeping the integrity of the original image is of top priority. Please note that most text does not convert well to a cut shape. Although the absence of text is preferred, it is highly recommended that any text be as simple and large as possible (see examples below).

Standard Custom Shape Examples

Additional Design Styles

2. Click below to complete the form where you can upload your shape and design.

We will send you a quote within 4 business days.

3. Place your order with a credit card or purchase order.

4. Upload your shape into your Design Center Software.